Ever wondered about acrylic plastic…..

Who invented acrylic?

Acrylic plastic was invented by the German chemists Fittig and Paul discovered the polymerization of acrylic plastic (poly(methyl methacrylate)) in 1877. In 1933 the German chemist Otto Röhm patented and registered the brand name PLEXIGLAS. In 1936 the first commercially viable production of acrylic safety glass began. During World War II acrylic glass was used for submarine periscopes, and windshields, canopies, and gun turrets for airplanes.

How is Acrylic plastic made?

Plastic acrylic sheets are formed by a process known as bulk polymerization. In this process, the monomer and catalyst are poured into a mould where the reaction takes place. Acrylic is also known as acrylic glass, Plexiglas, Lucite and Perspex. These are brand names, but they all are referring to the same product.

Can acrylic be recycled?

Yes, acyclic is 98% recyclable. We are dedicated to reducing waste, increasing efficiency and reusing and recycling waste wherever possible. We will always try to get the maximum amount of usage out of each sheet of material, with as little waste as we can. Therefore, if a plastic is required for a short-term use, we would generally recommend using acrylic or polycarbonate. This is due to their recycling properties. We offer free recycling of any acrylic or Polycarbonate, purchased from us.

Who sells Acrylic sheets?

We do! Our company, Abplas, offer a cut to size service. We can also polish and drill holes. You can choose a colour from the wide variety of colours we stock. If we haven’t got the colour you desire, we will order it for you.

What can acrylic be used for?

The possibilities are endless!

Firstly, sheets of acrylic are great for cladding bathrooms, as an alternative to tiles, and as splashbacks in kitchens. They are very hygienic, since they can easily be wiped clean. Acrylic splash backs do not have as many joins as tiles do. We recommend that you use soap and water to clean acrylic. Then use a dry cloth to remove any water marks. You can also buy special cleaners specifically for acrylic.

Secondly, acrylic can be used to offer protection to table tops. We can cut these to size for you.

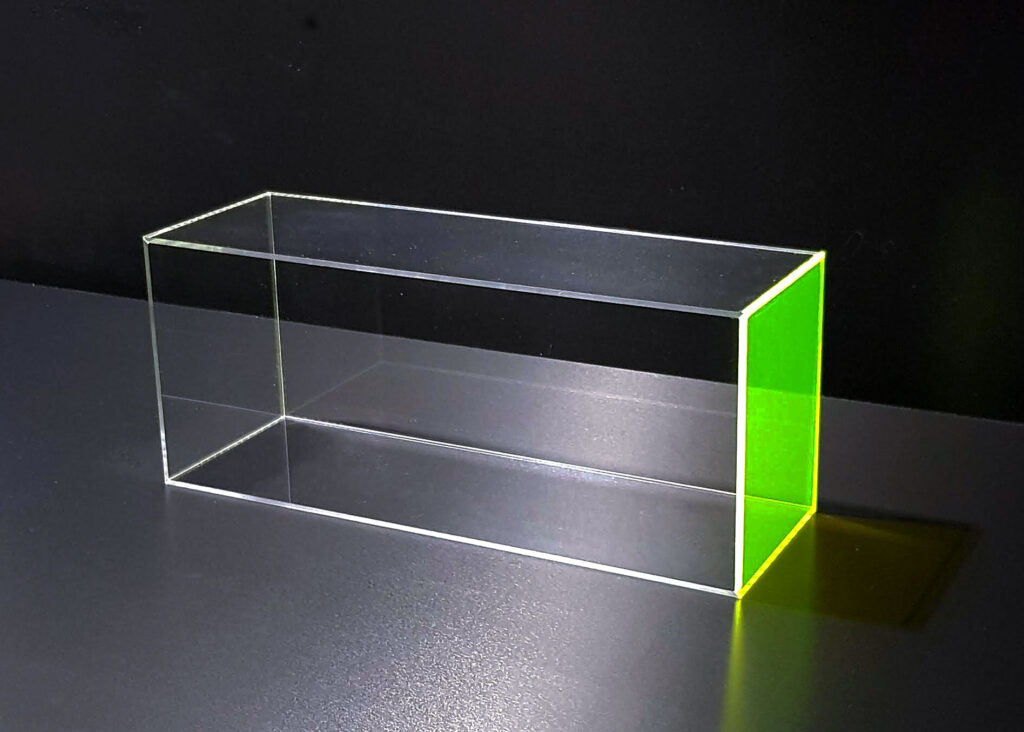

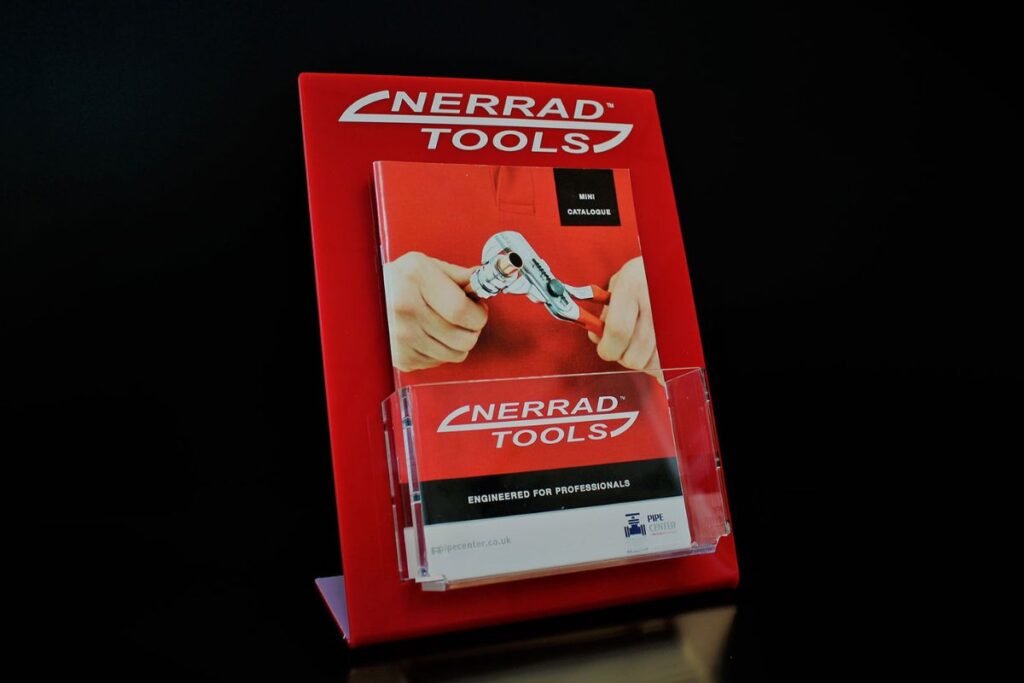

Moreover, we custom make acrylic display cases, leaflet holders, iPad stands, cake stands and canape trays, to name but a few! We use acrylic in our fabrication process in order to make centre pieces and signage. We supply many different industries and individuals. Our customer base is very varied. Our bespoke fabrication work means that we collaborate with a variety of people, from set designers, event companies, the retail sector, art galleries and museums to name but a few.

Are acrylic splashbacks any good?

We think they are great! They can be supplied in a wide range of colours. If you really want an individual and unique look, we can supply you with digitally printed acrylic splashbacks. All you have to do is let us know what design or picture you’d like.

Acrylic splashbacks are hygienic, easy to fit and are easy to clean. They are a quick and effective way of modernising an existing kitchen. Not only that, but they are great way of adding colour to a new kitchen. Acrylic splashbacks are also cheaper than toughened glass.

Find out more about some of our acrylic products